We use cookies to personalise content and ads, to provide social media features and to analyse our traffic. We also share information about your use of our site with our social media, advertising and analytics partners who may combine it with other information that you’ve provided to them or that they’ve collected from your use of their services. You consent to our cookies if you continue to use our website.

Building on many years of development activity, we produce an impressive range of high-performance bio lens that meet our customers’ demands for clear and sun lenses

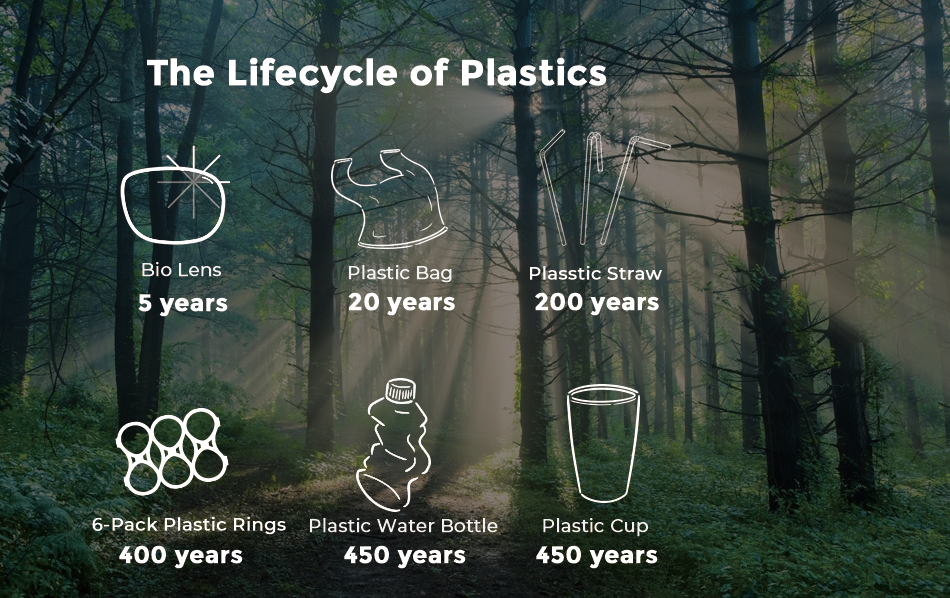

Bio Lens will start to bio-degrade in 10+ days, and takes around five years to biodegrade in landfills.

Bio Lens will eventually be naturally biodegraded into landfill, leaving carbon dioxide, water, and biomass.

By using Bio Lens, we are saving millions of lens used in the eyewear industry

Each year, 400 millions of ophthalmic frames produced in the industry and

The land needed to cover the AC lens each year equals to

Plastic takes thousands of years to disintegrate, but it will never really go away, leaving millions tons of plastics in the ocean.

In 2016, a global population of more than 7 billion people produced over 320 million tons of plastic. This is set to double by 2034.

Bio Lens starts to bio-degrade in 10+days in a landfill, which can be broken down into carbon, H2O, and organic matter.

It’s an intelligent, natural and eco-friendly.

Let’s create a Cleaner, Greener, Better World!

Biodegradable

Clear and Sun Lens

Optical Standards

High Impact Resistance

Coating Available

Each year, at least 8 million tonnes of plastics find their way into the ocean, the equivalent of dumping the contents of one garbage truck into the ocean every minute

OKIA has developed the Bio Lens, which could replace millions tons of lenses in the industry. Bio Lens is Biodegradable and can be broken down into water and biomass.

If the whole eyewear industry changed to Bio Lens, we can plant 688,750 trees and this equals to 3 Central Park

Bio Lens is not just only the lens, but we aim to provide the best quality of eco-friendly eyewear lenses to enhance people’s visual experience

With an in-depth research and development, our RND team find the secret recipe for both bio-degradable Clear lens and Sun lens

Our expertise in production and development is backed by over 20 years’ experience in making high performance bio lens.

We’ve put everything in place to ensure the quality. Bio Lens meets the Optical Standards, which at the same time provides high durability and high impact resistance.

Bio Lens has all the related testing reports for worldwide standards.

Bio Degradable Polymer

| Properties/Features |

|---|

| Bio Degradable |

| Broken into Carbon, H2O, and Organic Matter |

| Clear and Sun Lens Available |

| High Impact Resistance |

| Coating Available (e.g Mirror Coating, AR Coating, Anti-Scratch Coating, UV Coating) |

| High performance lens for different styles, shapes, curvatures, and sizes |

| UV Protection for Bio Degradable Sun Lens |

| Standards |

|---|

| ASTM D5511 |

| ANSI 87.1 |

| FDA |

| CE |